Page 172 - Praxair Productivity Catalog

P. 172

WELDING AUTOMATION

ProStar Robotic Welding Cells

™

Your Choice of Robotics & Welding OEMs

Inside a Pre-Engineered Praxair Work Cell

FREEDOM OF CHOICE

With a broad range of automation

and welding process options,

ProStar robotic cells are the ideal

choice for production of repetitive

parts of nearly any shape or size.

Praxair’s extensive line of welding

cells supports a variety of OEM

options. Customers can choose

from among the major brands of

six-axis robotic arms, controllers,

positioners and consumables.

ProStar cells come standard in

a number of confi gurations for

weldment size and shape, loading,

alternating work stations, modular

tables, ferris-wheel operation,

multi-axis positioners, and more!

Choose your preferred robot

and welding process...

Specify single or multi-axis

positioners

Choose one, two, or three

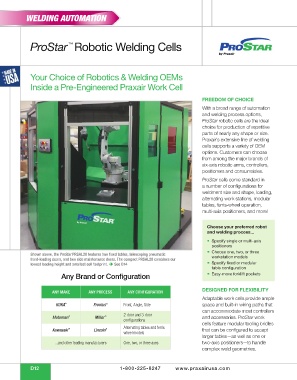

Shown above, the ProStar PRSAL20 features two fi xed tables, telescoping pneumatic workstation models

front-loading doors, and two side maintenance doors. The compact PRSAL20 combines our

lowest loading height and smallest cell footprint. See D14 Specify fi xed or modular

table confi guration

Any Brand or Confi guration Easy-move forklift pockets

ANY MAKE ANY PROCESS ANY CONFIGURATION DESIGNED FOR FLEXIBILITY

Adaptable work cells provide ample

KUKA ® Fronius ® Front, Angle, Side space and built-in wiring paths that

can accommodate most controllers

2-door and 3-door

Motoman ® Miller ® and accessories. ProStar work

confi gurations

cells feature modular tooling bridles

Alternating tables and ferris

Kawasaki ® Lincoln ® that can be confi gured to accept

wheel models

larger tables—as well as one or

...and other leading manufacturers One, two, or three axes two-axis positioners—to handle

complex weld geometries.

D12 1-800-225-8247 www.praxairusa.com