Page 167 - Praxair Productivity Catalog

P. 167

Robotics Welding Cells

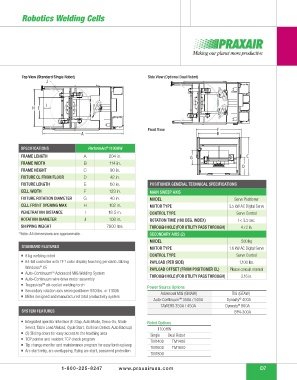

Top View (Standard Single Robot) Side View (Optional Dual Robot)

Front View

SPECIFICATIONS PerformArc 1100HW

®

FRAME LENGTH A 204 in.

FRAME WIDTH B 114 in.

FRAME HEIGHT C 90 in.

FIXTURE CL FROM FLOOR D 42 in.

FIXTURE LENGTH E 60 in. POSITIONER GENERAL TECHNICAL SPECIFICATIONS

CELL WIDTH F 123 in. MAIN SWEEP AXIS

FIXTURE ROTATION DIAMETER G 40 in. MODEL Servo Positioner

CELL FRONT OPENING MAX H 102 in. MOTOR TYPE 3.5 kW AC Digital Servo

PENETRATION DISTANCE I 18.5 in. CONTROL TYPE Servo Control

ROTATION DIAMETER J 108 in. ROTATION TIME (180 DEG. INDEX) t < 3.5 sec.

SHIPPING WEIGHT 7600 lbs. THROUGH HOLE (FOR UTILITY PASS THROUGH) 4.72 in.

*Note: All dimensions are approximate. SECONDARY AXIS (2)

MODEL 500 kg

STANDARD FEATURES MOTOR TYPE 1.6 kW AC Digital Servo

6 kg welding robot CONTROL TYPE Servo Control

64-bit controller with TFT color display teaching pendant utilizing PAYLOAD (PER SIDE) 1,100 lbs.

Windows CE PAYLOAD OFFSET (FROM POSITIONER CL) Please consult manual

®

Auto-Continuum Advanced MIG Welding System

TM

Auto-Continuum wire drive motor assembly THROUGH HOLE (FOR UTILITY PASS THROUGH) 2.16 in.

Tregaskiss air-cooled welding torch Power Source Options

TM

Secondary rotation axis servo positioner 550 lbs. or 1100lb Advanced MIG (GMAW) TIG (GTAW)

Miller designed and manufactured total productivity system

®

Auto-Continuum 350A / 500A Dynasty 400A

TM

TAWERS 350A / 450A Dynasty 800A

®

SYSTEM FEATURES BP4-300A

Integrated operator interface (E-Stop, Auto Mode, Servo On, Mode Robot Options

Select, Table Load/Unload, Cycle Start, Collision Detect, Auto Backup) 1100HW

(2) Sliding doors for easy access to the teaching area Single Dual Robot

TCP pointer and resident TCP check program TM1400 TM1400

Tip change monitor and maintenance program for easy torch upkeep TM1600 TM1600

Arc start retry, arc overlapping, fl ying arc start, password protection

TM1800

1-800-225-8247 www.praxairusa.com D7