Page 163 - Praxair Productivity Catalog

P. 163

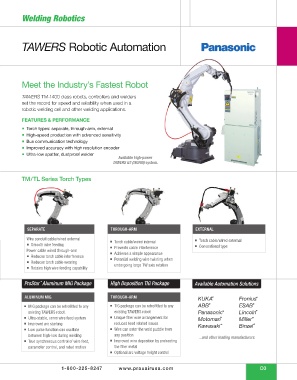

Welding Robotics

TAWERS Robotic Automation

Meet the Industry’s Fastest Robot

TAWERS TM-1400 class robots, controllers and welders

set the record for speed and reliability when used in a

robotic welding cell and other welding applications.

FEATURES & PERFORMANCE

Torch types: separate, through-arm, external

High-speed production with advanced sensitivity

Bus communication technology

Improved accuracy with high resolution encoder

Ultra-low spatter, dustproof welder

Available high-power

TAWERS G3 (WGHIII) system.

TM/TL Series Torch Types

SEPARATE THROUGH-ARM EXTERNAL

Wire conduit cable/wired external Torch cable/wired internal Torch cable/wired external

Smooth wire feeding Prevents cable interference Conventional type

Power cable wired through-arm Achieves a simple appearance

Reduces torch cable interference Potential welding wire twisting when

Reduces torch cable wearing undergoing large TW axis rotation

Retains high wire feeding capability

ProStar Aluminum MIG Package High Deposition TIG Package Available Automation Solutions

™

ALUMINUM MIG THROUGH-ARM KUKA ® Fronius ®

MIG package can be retrofi tted to any TIG package can be retrofi tted to any ABB ® ESAB ®

existing TAWERS robot. existing TAWERS robot Panasonic ® Lincoln ®

Ultra-stable, servo wire feed system Unique fi ller wire arrangement for Motoman ® Miller ®

Improved arc starting reduced feed related issues Kawasaki ® Binzel ®

Low pulse function can oscillate Wire can enter the weld puddle from

between high-low during welding any position ...and other leading manufacturers.

True synchronous control of wire feed, Improved wire deposition by preheating

parameter control, and robot motion the fi ller metal

Optional arc voltage height control

1-800-225-8247 www.praxairusa.com D3