Page 175 - Praxair Productivity Catalog

P. 175

Robotics Welding Cells

Servo-Indexing Work Cells

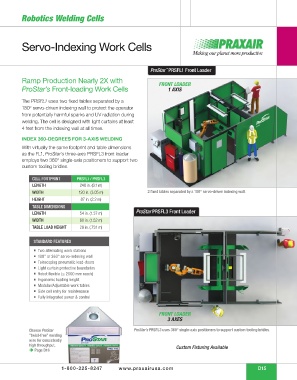

ProStar PRSFL1 Front Loader

™

Ramp Production Nearly 2X with FRONT LOADER

ProStar’s Front-loading Work Cells 1 AXIS

The PRSFL1 uses two fi xed tables separated by a

180° servo-driven indexing wall to protect the operator

from potentially harmful sparks and UV radiation during

welding. The cell is designed with light curtains at least

4 feet from the indexing wall at all times.

INDEX 360-DEGREES FOR 3-AXIS WELDING

With virtually the same footprint and table dimensions

as the FL1, ProStar’s three-axis PRSFL3 front loader

employs two 360° single-axis positioners to support two

custom tooling bridles.

CELL FOOTPRINT PRSFL1 / PRSFL3

LENGTH 240 in. (6.1 m)

WIDTH 120 in. (3.05 m) 2 fi xed tables separated by a 180° servo-driven indexing wall.

HEIGHT 87 in. (2.2 m)

TABLE DIMENSIONS

LENGTH 54 in. (1.37 m) ProStar PRSFL3 Front Loader

WIDTH 60 in. (1.52 m)

TABLE LOAD HEIGHT 29 in. (.731 m)

STANDARD FEATURES

Two alternating work stations

180° or 360° servo-indexing wall

Telescoping pneumatic load-doors

Light curtain protective boundaries

Robot fl exible (≤ 2000 mm reach)

Ergonomic loading height

Modular/Adjustable work tables

Side cell entry for maintenance

Fully integrated power & control

FRONT LOADER

3 AXES

Choose ProStar ProStar’s PRSFL3 uses 360° single-axis positioners to support custom tooling bridles.

”twist-free” welding

wire for consistently

high throughput. Custom Fixturing Available

Page D18

1-800-225-8247 www.praxairusa.com D15