Page 176 - Praxair Productivity Catalog

P. 176

WELDING AUTOMATION

High Effi ciency Work Cells

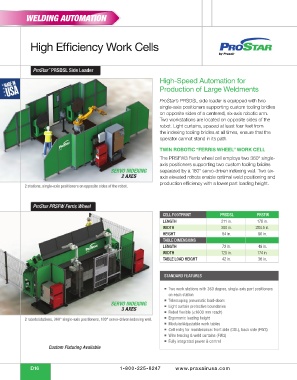

ProStar PRSDSL Side Loader

™

High-Speed Automation for

Production of Large Weldments

ProStar’s PRSDSL side loader is equipped with two

single-axis positioners supporting custom tooling bridles

on opposite sides of a centered, six-axis robotic arm.

Two workstations are located on opposite sides of the

robot. Light curtains, spaced at least four feet from

the indexing tooling bridles at all times, ensure that the

operator cannot stand in its path.

TWIN ROBOTIC “FERRIS WHEEL” WORK CELL

The PRSFW3 Ferris wheel cell employs two 360° single-

axis positioners supporting two custom tooling bridles

SERVO INDEXING separated by a 180° servo-driven indexing wall. Two six-

2 AXES axis elevated robots enable optimal weld positioning and

production effi ciency with a lower part loading height.

2 stations, single-axis positioners on opposite sides of the robot.

ProStar PRSFW Ferris Wheel

CELL FOOTPRINT PRSDSL PRSFW

LENGTH 211 in. 178 in.

WIDTH 300 in. 284.5 in.

HEIGHT 84 in. 80 in.

TABLE DIMENSIONS

LENGTH 72 in. 48 in.

WIDTH 120 in. 174 in.

TABLE LOAD HEIGHT 42 in. 36 in.

STANDARD FEATURES

Two work stations with 360 degree, single-axis part positioners

on each station

Telescoping pneumatic load-doors

SERVO INDEXING

3 AXES Light curtain protective boundaries

Robot fl exible (≤1600 mm reach)

2 robots/stations, 360° single-axis positioners, 180° servo-driven indexing wall. Ergonomic loading height

Modular/Adjustable work tables

Cell entry for maintenance: front side (DSL), back side (FW3)

Wire fencing & weld curtains (FW3)

Fully integrated power & control

Custom Fixturing Available

D16 1-800-225-8247 www.praxairusa.com