Page 118 - ProStar Product Guide

P. 118

FILLER METALS

™

ProStar Shielded Flux-Cored Wire

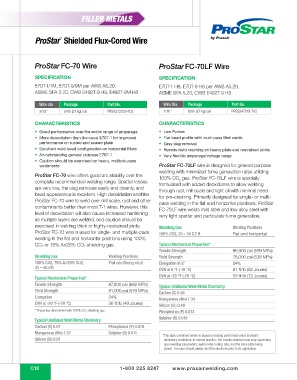

ProStar FC-70 Wire ProStar FC-70LF Wire

SPECIFICATION SPECIFICATION

E70T-1/1M, E70T-9/9M per AWS A5.20, E70T-1 H8, E70T-9 H8 per AWS A5.20,

ASME SFA 5.20, CWB E492T-9 H8, E492T-9M H8 ASME SFA 5.20, CWB E492T-9 H8

Wire dia Package Part No. Wire Dia Package Part No.

3/32" 60 lb (27 kg) coil PRSS272029-702 1/16" 60 lb (27 kg) coil PRSS247019-702

CHARACTERISTICS CHARACTERISTICS

• Good performance over the entire range of amperage • Low Fumes

• More deoxidation than the usual E70T-1 for improved • Flat bead profile with multi-pass fillet welds

performance on rusted and scaled plate • Easy slag removal

• Excellent weld bead configuration on horizontal fillets • Resists weld cracking on heavy plate and restrained joints

• An outstanding general purpose E70T-1 • Very flexible amperage/voltage range

• Caution should be exercised on heavy, multiple-pass

weldments ProStar FC-70LF wire is designed for general-purpose

welding with minimized fume generation rates utilizing

ProStar FC-70 wire offers good arc stability over the

100% CO gas. ProStar FC-70LF wire is specially

complete recommended welding range. Spatter losses 2

formulated with added deoxidizers to allow welding

are very low, the slag removes easily and cleanly, and

through rust, mill scale and light oil with minimal need

bead appearance is excellent. High deoxidation enables

for pre-cleaning. Primarily designed for single- or multi-

ProStar FC-70 wire to weld over mill scale, rust and other

pass welding in the flat and horizontal positions, ProStar

contaminants better than most T-1 wires. However, this

FC-70LF wire welds mild steel and low alloy steel with

level of deoxidation will also cause increased hardening

very light spatter and particulate fume generation.

as multiple layers are welded, and caution should be

exercised in welding thick or highly-restrained joints. Shielding Gas Welding Positions

ProStar FC-70 wire is used for single- and multiple-pass 100% CO2, 35 – 50 C.F.H. Flat and horizontal

welding in the flat and horizontal positions using 100%

CO 2 or 75% Ar/25% CO 2 shielding gas. Typical Mechanical Properties*

Tensile Strength 86,900 psi (599 MPa)

Shielding Gas Welding Positions Yield Strength 78,000 psi (538 MPa)

100% CO2, 75% Ar/25% CO2, Flat and horizontal Elongation in 2" 24%

35 – 50 cfh

CVN at 0 °F (-18 °C) 61 ft/lb (82 Joules)

CVN at -20 °F (-29 °C) 53 ft/lb (72 Joules)

Typical Mechanical Properties*

Tensile Strength 87,000 psi (662 MPa)

Typical Undiluted Weld Metal Chemistry

Yield Strength 81,000 psi (579 MPa)

Carbon (C) 0.24

Elongation 24%

Manganese (Mn) 1.34

CVN at -20 °F (-29 °C) 36 ft/lb (49 Joules)

Silicon (Si) 0.49

* Properties determined with 100% CO shielding gas

2 Phosphorus (P) 0.013

Sulphur (S) 0.010

Typical Undiluted Weld Metal Chemistry

Carbon (C) 0.07 Phosphorus (P) 0.010

Manganese (Mn) 1.37 Sulphur (S) 0.011

* The data contained herein is based on testing performed under standard

Silicon (Si) 0.61 laboratory conditions. In normal practice, the results obtained may vary depending

upon welding parameters, weld metal cooling rate, and the base plate being

joined. The user should always test the electrode prior to its application.

C18 1-800 225 8247 www.praxairwelding.com