Page 118 - Praxair Productivity Catalog

P. 118

METAL FORMING

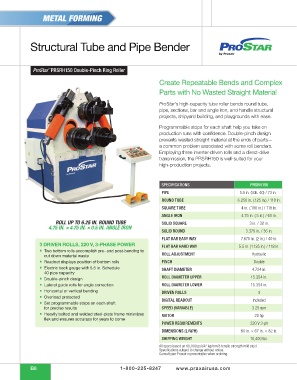

Structural Tube and Pipe Bender

ProStar PRSRH150 Double-Pinch Ring Roller

™

Create Repeatable Bends and Complex

Parts with No Wasted Straight Material

ProStar’s high-capacity tube roller bends round tube,

pipe, sections, bar and angle iron, and handle structural

projects, shipyard building, and playgrounds with ease.

Programmable stops for each shaft help you take on

production runs with confi dence. Double-pinch design

prevents wasted straight material at the ends of parts—

a common problem associated with some roll benders.

Employing three inverter-driven rolls and a direct-drive

t transmission, the PRSRH150 is well-suited for yourransmission, the PRSRH150 is well-suited for your

high-production projects.

SPECIFICATIONS PRSRH150

PIPE 5.5 in. (Sch. 40) / 73 in.

ROUND TUBE 6.250 in. (.125 in.) / 118 in.

SQUARE TUBE 4 in. (.196 in.) / 118 in.

ANGLE IRON 4.75 in. (.5 in.) / 60 in.

ROLL UP TO 6.25 IN. ROUND TUBE SOLID SQUARE 3 in. / 32 in.

4.75 IN. × 4.75 IN. × 0.5 IN. ANGLE IRON

SOLID ROUND 3.375 in. / 36 in.

FLAT BAR EASY WAY 7.875 in. (2 in.) / 40 in.

3 DRIVEN ROLLS, 220 V, 3-PHASE POWER FLAT BAR HARD WAY 5.5 in. (1.125 in.) / 118 in.

Two bottom rolls accomplish pre- and post-bending to

cut down material waste ROLL ADJUSTMENT Hydraulic

Readout displays position of bottom rolls PINCH Double

Electric back gauge with 5.5 in. Schedule SHAFT DIAMETER 4.724 in.

40 pipe capacity

Double-pinch design ROLL DIAMETER UPPER 15.354 in.

Lateral guide rolls for angle correction ROLL DIAMETER LOWER 15.354 in.

Horizontal or vertical bending DRIVEN ROLLS 3

Overload protected DIGITAL READOUT Included

Set programmable stops on each shaft

for precise results SPEED (VARIABLE) 3.25 rpm

Heavily bolted and welded steel-plate frame minimizes MOTOR 20 hp

fl ex and ensures accuracy for years to come

POWER REQUIREMENTS 220 V 3-ph

DIMENSIONS (L/W/H) 80 in. × 67 in. × 82 in.

SHIPPING WEIGHT 10,400 lbs.

All specs based on 60,000 psi (42 kg/mm2) tensile strength mild steel.

Specifi cations subject to change without notice.

Consult your Praxair representative when ordering.

B8 1-800-225-8247 www.praxairusa.com