Page 104 - ProStar Product Guide

P. 104

FILLER METALS

Twist-Free Welding Wire System

Straight & Clean from Beginning to End WHAT DOES “TWIST-FREE”

MEAN IN A WELDING WIRE?

ProStar welding wire is the right choice for weldr • “Twist-free” means the drawing

productivity and quality—formulated for both and packaging process results

manual and robotic welding. in a product with very little cast

or helix – wire comes out of

its packaging much straighter

compared to standard wires.

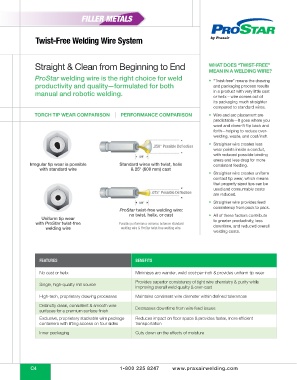

TORCH TIP WEAR COMPARISON | PERFORMANCE COMPARISON • Wire and arc placement are

predictable—it goes where you

want and doesn’t flip back and

forth—helping to reduce over-

welding, waste, and cost/inch.

• Straighter wire creates less

.250" Possible Deflection

wear points inside a conduit,

with reduced possible binding

areas and less drag for more

Irregular tip wear is possible Standard wires with twist, helix consistent feeding.

with standard wire & 25" (600 mm) cast

• Straighter wire creates uniform

contact tip wear, which means

that properly sized tips can be

used and consumable costs

.075" Possible Deflection

are reduced.

• Straighter wire provides feed

consistency from pack to pack.

ProStar twist-free welding wire: r

no twist, helix, or cast • All of these factors contribute

Uniform tip wear

with ProStar twist-freer Possible performance variance between standard to greater productivity, less

downtime, and reduced overall

welding wire welding wire & ProStar twist-free welding wire.r

welding costs.

FEATURES BENEFITS

No cast or helix Minimizes arc wander, weld cost-per-inch & provides uniform tip wear

Provides superior consistency of tight wire chemistry & purity while

Single, high-quality mill source

improving overall weld quality & over-cast

High-tech, proprietary drawing processes Maintains consistent wire diameter within defined tolerances

Distinctly clean, consistent & smooth wire Decreases downtime from wire feed issues

surfaces for a premium surface finish

Exclusive, proprietary stackable wire package Reduces impact on floor space & provides faster, more efficient

containers with lifting access on four sides transportation

Inner packaging Cuts down on the effects of moisture

C4 1-800 225 8247 www.praxairwelding.com