Page 51 - Praxair Productivity Catalog

P. 51

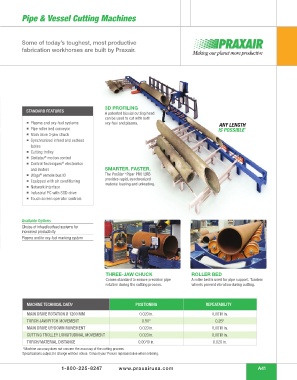

Pipe & Vessel Cutting Machines

Some of today’s toughest, most productive

fabrication workhorses are built by Praxair.

3D PROFILING

STANDARD FEATURES A patented biaxial cutting head

can be used to cut with both

Plasma and oxy-fuel systems oxy-fuel and plasma. ANY LENGTH

Pipe roller bed conveyor IS POSSIBLE *

Main drive 3-jaw chuck

Synchronized infeed and outfeed

tables

Cutting trolley

Deltatau motion control

®

Control Techniques electronics

®

and motors SMARTER. FASTER.

™

®

Wago remote bus IO The ProStar Piper PRO12RB

Equipped with air conditioning provides rapid, synchronized

material loading and unloading.

Network interface

Industrial PC with SSD drive

Touch screen operator controls

Available Options

Choice of infeed/outfeed systems for

increased productivity

Plasma and/or oxy-fuel marking system

THREE-JAW CHUCK ROLLER BED

Comes standard to ensure precision pipe A roller bed is used for pipe support. Tandem

rotation during the cutting process. wheels prevent vibration during cutting.

MACHINE TECHNICAL DATA † POSITIONING REPEATABILITY

MAIN DRIVE ROTATION Ø 1200 MM 0.020 in. 0.0010 in.

TORCH JAW/PITCH MOVEMENT 0.50° 0.25°

MAIN DRIVE UP/DOWN MOVEMENT 0.020 in. 0.0010 in.

CUTTING TROLLEY LONGITUDINAL MOVEMENT 0.020 in. 0.0010 in.

TORCH/MATERIAL DISTANCE 0.0040 in. 0.020 in.

† Machine accuracy does not concern the accuracy of the cutting process.

Specifi cations subject to change without notice. Consult your Praxair representative when ordering.

1-800-225-8247 www.praxairusa.com A41