Page 37 - Praxair Productivity Catalog

P. 37

Praxair’s Plate Cutting Gases

Praxair’s Gases for

Plasma Cutting

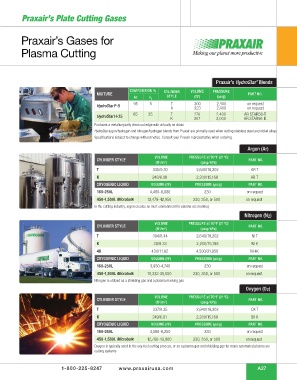

Praxair’s HydroStar Blends

®

COMPOSITION % CYLINDER VOLUME PRESSURE

MIXTURE PART NO.

3

Ar H 2 STYLE (ft ) (psig)

95 5 T 300 2,400 on request

HydroStar F-5

K 223 2,400 on request

HydroStar H-35 65 35 T 276 2,400 AR STAR56-T

207

AR STAR56-K

K

2,000

Produces a metallurgically clean cut edge with virtually no dross

HydroStar argon/hydrogen and nitrogen/hydrogen blends from Praxair are primarily used when cutting stainless steel and nickel alloys

Specifi cations subject to change without notice. Consult your Praxair representative when ordering.

Argon (Ar)

VOLUME PRESSURE at 70°F (21°C)

CYLINDER STYLE PART NO.

3

(ft /m ) (psig/kPa)

3

T 335/9.30 2,640/18,202 AR T

K 248/6.88 2,200/15,168 AR T

CRYOGENIC LIQUID VOLUME (ft ) PRESSURE (psig) PART NO.

3

160-250L 4,460-6,080 230 on request

450-1,500L Microbulk 12,478-42,950 230, 350, or 500 on request

In the cutting industry, argon creates an inert environment for plasma arc marking

Nitrogen (N2)

VOLUME PRESSURE at 70°F (21°C)

CYLINDER STYLE PART NO.

(ft /m ) (psig/kPa)

3

3

T 304/8.44 2,640/18,202 NI T

K 28/6.33 2,200/15,168 NI K

4K 430/11.92 4,500/31,050 NI 4K

CRYOGENIC LIQUID VOLUME (ft ) PRESSURE (psig) PART NO.

3

160-250L 3,930-4,740 230 on request

450-1,500L Microbulk 10,332-35,550 230, 350, or 500 on request

Nitrogen is utilized as a shielding gas and a plasma marking gas

Oxygen (O2)

VOLUME PRESSURE at 70°F (21°C)

CYLINDER STYLE PART NO.

(ft /m ) (psig/kPa)

3

3

T 337/9.35 2,640/18,202 OX T

K 249/6.91 2,200/15,168 OX K

CRYOGENIC LIQUID VOLUME (ft ) PRESSURE (psig) PART NO.

3

160-250L 4,580-6,250 230 on request

450-1,500L Microbulk 12,760-43,900 230, 350, or 500 on request

Oxygen is typically used in the oxy-fuel cutting process, or as a plasma gas and shielding gas for many automated plasma arc

cutting systems

1-800-225-8247 www.praxairusa.com A27